4MOST Cassegrain Cable Wrap Factory Acceptance

by Joe Liske on 2021-05-17

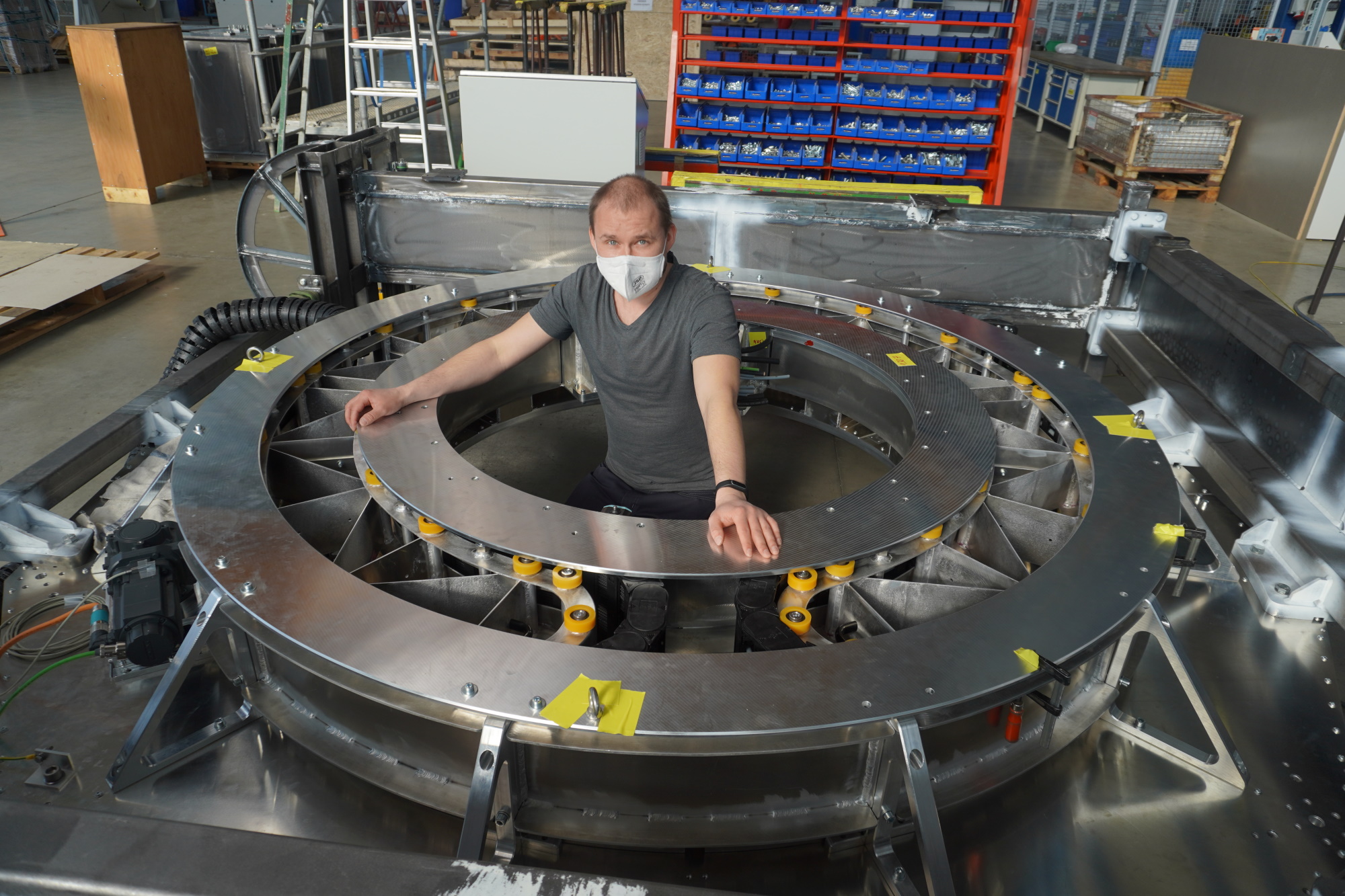

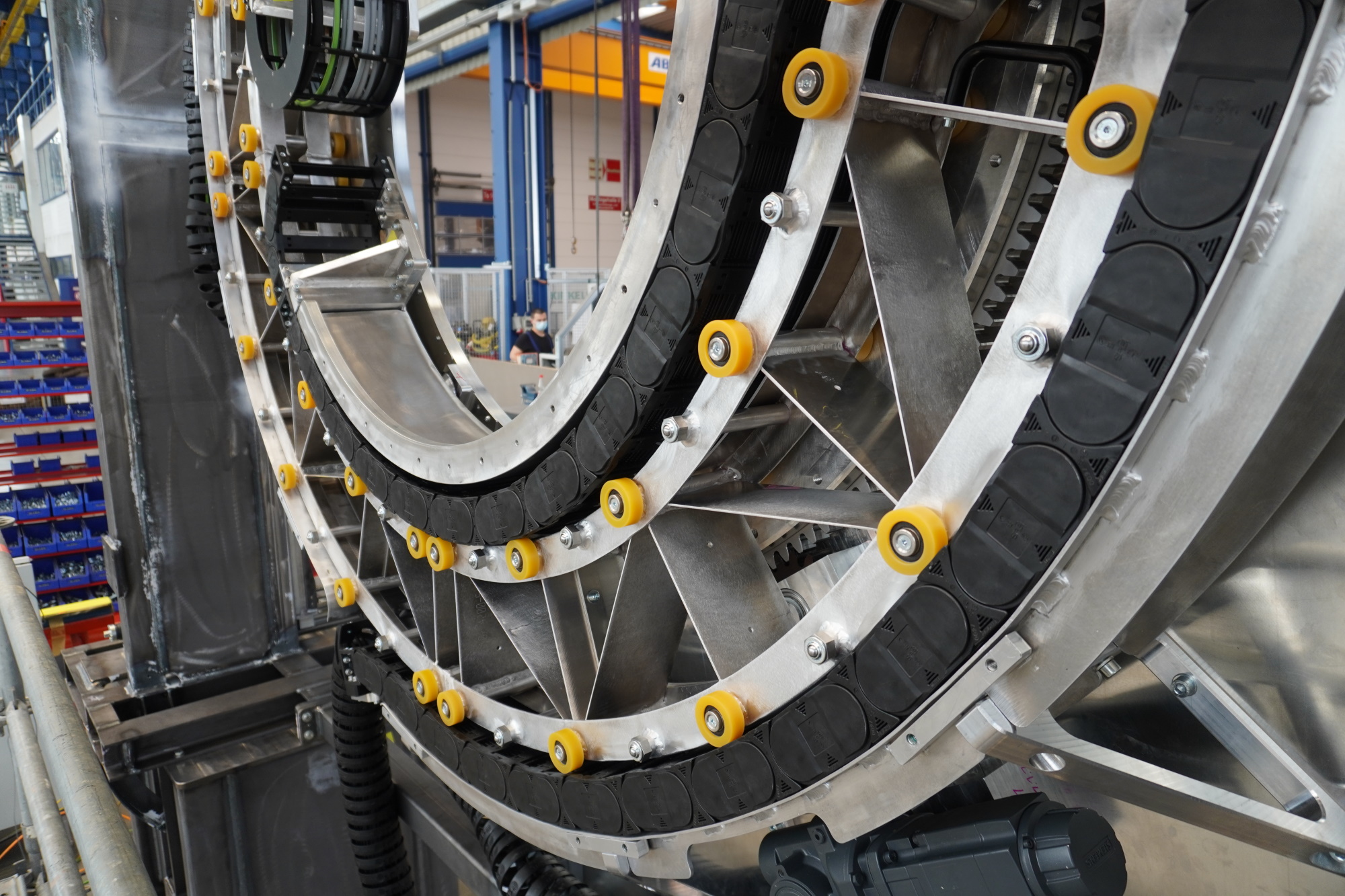

The production of hardware for 4MOST is in full swing. One of the major electro-mechanical systems in production is the 4MOST Cassegrain Cable Wrap (CaCW). This system is required to de-rotate not only electrical, network, and cooling supplies to the fiber positioner AESOP, but also all optical fibers connecting AESOP to the three spectrographs. On the telescope, we have to rotate AESOP to track the stars on sky, and we need a way to safely manage all these connections to the Azimuth platform. The way we do this is through an electrically driven de-rotator. The detailed design, analysis, parts machining and assembly was contracted to the company Kinkele in the north of Bavaria. After completion, staff from the AIP spent three weeks on site at Kinkele to inspect and verify the CaCW. The campaign was successful and concluded with a punch list of issues to resolve before shipping to the AIP, which is scheduled for the first half of June 2021.

Allar Saviauk, CaCW lead engineer: "I was happy to see the CaCW structure finally in front of us after so many years of development and hard work. This system took several design revisions and tweaks before we were confident submitting it for manufacturing. We showed up at the manufacture's plant with our long test plan, and over a two and a half week period we were able to check all the dimensions, welds, load testing and of course the functionality itself. The first time we rotated the fully loaded system with chains was quite exiting! Fortunately, the CaCW works as intended and we were able to rotate this Stargate-like system by +/-200 deg in various telescope pointing angles. Some optimization is still required in the fibre cable configuration inside the energy chain. Our fibre team is currently working on a solution. The company is also re-manufacturing one of the welded assemblies to improve the dimensional fit to other components. In general I'm very pleased about the results and want to thank everybody involved with this system over the years: A. Kelz, J. Brynnel, S. Bauer, T. Jahn, L. Wagner, J. Paschke, R. Haynes, T. Liebner (AIP), M. Lehmitz (MPIA), and A. Jost (ESO)."