News

4MOST Science Team Meeting 2022

2022-05-27

The 4MOST Science Team Meeting 2022 was held at Hamburg University and online on 23 – 25 May 2022. This was the first STM to include the members of the recently selected Community Surveys and it represented the endpoint of the community onboarding programme, thus completing the integration of the Community Surveys into the 4MOST Science Team. With 168 registered participants, of which ~80 were present in Hamburg, the programme mainly revolved around discussions within and among the various Surveys and Infrastructure Working Groups. Reassuringly, after two years of pandemic and with many new colleagues having joined the team, the collaborative spirit of the 4MOST Science Team was found to be as healthy as ever.

Introducing the new Ombudspersons

2022-05-22

The 4MOST Project is pleased to announced that two Ombudspersons are now available for all 4MOST members. The role of the Ombudspersons is to provide informal, confidential, nonjudgmental, impartial, and independent advice, and to arrange mediation for 4MOST members for the purpose of dispute resolution (see the full guidelines). The two Ombudspersons are Chiara Battistini cbattistini@lsw.uni-heidelberg.de of Heidelberg University and Alastair Edge of Durham University. The search for a third Ombudsperson will be launched soon.

Chiara studies the evolution of element abundances in the Milky Way. She was a PhD student representative on the departmental board at Lund Observatory and is currently a postdoc representative at the Zentrum für Astronomie (ZAH) in Heidelberg. She has been involved in 4MOST since 2015 and is an active member of the Milky Way Halo High Resolution Survey and several working groups (IWG1, IWG2 and IWG7). She is also the science representative of ZAH in the 4MOST STSC.

What motivated Chiara to become a 4MOST Ombudsperson? “Having been involved in 4MOST for several years gives me a good perspective on the full project, all its ramifications and the potential issues that might appear. At the same time, being an early career scientist and not involved in any high level position inside 4MOST makes me easily approachable in case of issues, especially from peers. I also think that during these years I showed dedication and availability, so also for more senior scientists I should be easily reachable and they would feel that I can take care of the issues they might have in a concrete way.”

Alastair works on galaxy clusters and AGN using radio, X-ray and optical observations and is a member of the Galaxy Clusters Survey. He has been the departmental Equality and Diversity lead, sat on a number of university wide committees, and is co-Chair of the LSST:UK Board.

Regarding his motivation to become a 4MOST Ombudsperson he says: “I have extensive experience of large international collaborations over the last three decades. These projects range from the ROSAT All-Sky Survey to SKA precursor radio surveys. I am familiar with the breadth and diversity of the 4MOST science projects and the groups leading them. From experience, I am aware of the importance of a strong collaborative culture within projects and will strive to uphold and promote that throughout the 4MOST community. This role may be viewed as more of a “referee” but I hope that I can be as much a “coach” ensuring that the early career researchers that are so vital to the success of 4MOST are given the space to thrive.”

LRS-A arrives in Potsdam

2022-03-31

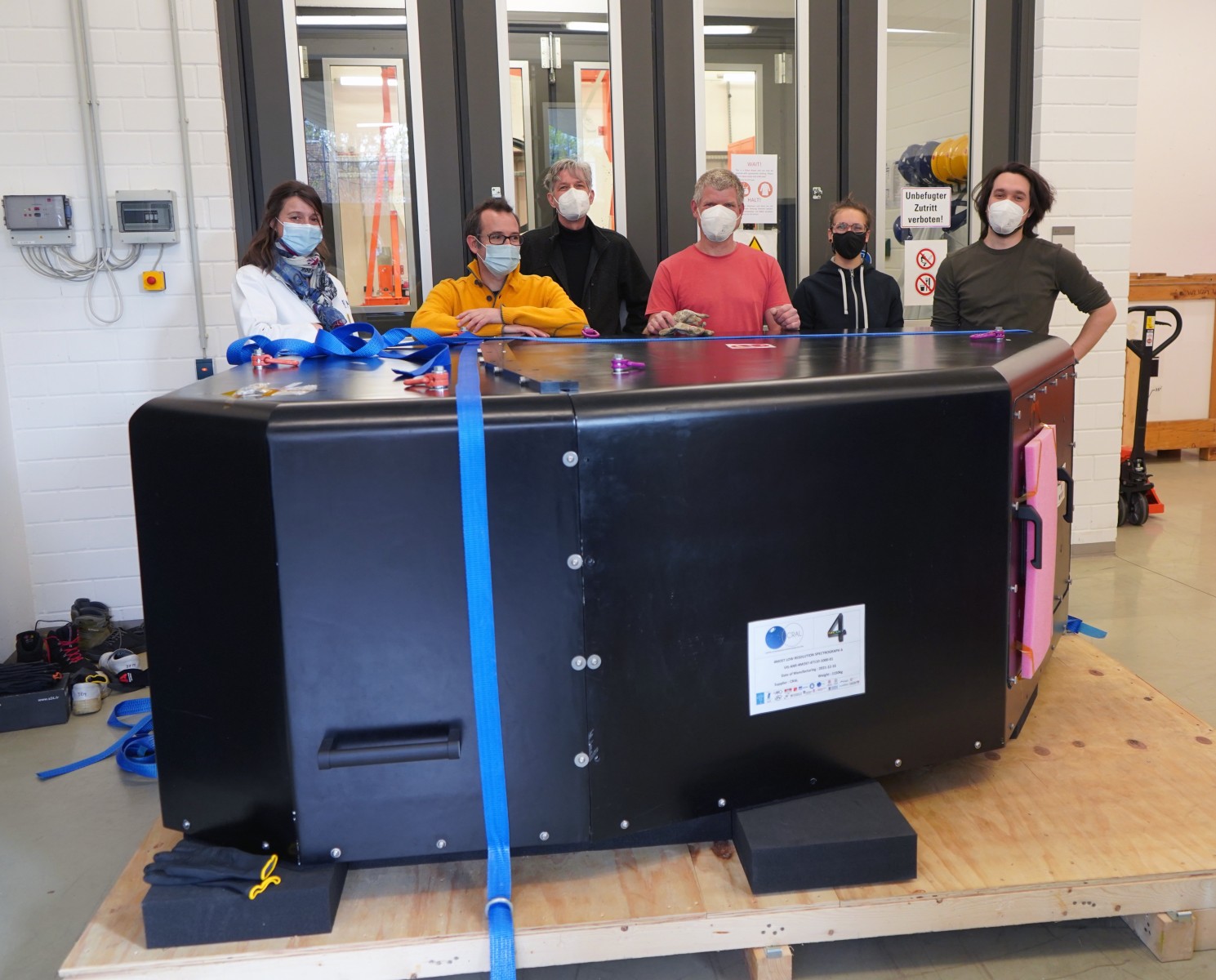

4MOST is built around three spectrographs that will collect the spectra of up to 2436 astronomical objects simultaneously. Two of these are identical low-resolution spectrographs (LRS), one is a high-resolution spectrograph (HRS), each fed by 812 fibres. Each spectrograph has a blue, green and red arm, in fixed configuration, and each arm is equipped with a 6k × 6k CCD detector. The two LRS provide continuous wavelength coverage from 390 to 950 nm at a resolution of R > 4000. Once completed, all three spectrographs will be sent to the AIP for system testing and validation.

In December 2021, integration of the first of the three spectrographs (LRS-A) was completed at the 4MOST consortium institute CRAL in Lyon. After acceptance testing, it was disassembled and packed in preparation of shipment to the AIP. On 29 March 2022 the disassembled LRS-A arrived at the AIP on four trucks. A team of five colleagues from CRAL, supported by the 4MOST AIP integration team and two colleagues from MPIA Heidelberg will spend the better part of the three following weeks to unpack and reassemble the spectrograph.

The delivery of LRS-A is a major milestone for the 4MOST project and we are very excited to receive it and follow its re-integration in the integration hall. The two remaining spectrographs are scheduled for delivery to the AIP in August and October of 2022.

See also this AIP press release.

Community Surveys selected

2022-02-04

During the first five years of 4MOST operations, 30% of the available observing time will be used for conducting a set of surveys initiated by the ESO community. The two-step selection process for these surveys, which began in 2019, has now been completed: ESO has announced the selection of 15 Community Surveys, covering a wide range of Galactic and extragalactic science cases. These will now join the existing 10 Consortium Surveys to form the final 4MOST survey programme. The completion of its survey programme is a major milestone for the 4MOST project, and the 4MOST consortium would like to extend a very warm welcome to the Community Survey teams. "We are very glad to have these Surveys on board as they will significantly enhance the scientific scope of the 4MOST survey programme. We are looking forward to a close collaboration in exploiting the many exciting scientific opportunities that lie ahead," said Roelof de Jong, the 4MOST Principal Investigator.

The next step is to integrate the Community Surveys into the existing 4MOST Science Team, and to familiarize the new members with the complexities of 4MOST operations and the management of the project. To this end, the consortium has prepared an extensive "onboarding" programme, consisting of eight online training sessions and culminating in the Science Team meeting in May 2022. The first three of the online sessions will be held twice in order to accommodate participants from all time zones. They will also be recorded and the recordings will be made available here afterwards. The connection details will be distributed by email. The training sessions are open to all members of the Community Surveys as well as to all existing 4MOST members. The programme for the online training sessions is listed below.

| Session 1 |

|

||

| 2022-02-10 | 15:30 – 17:30 CET | ||

| 2022-02-11 | 09:30 – 11:30 CET | ||

| Session 2 |

|

||

| 2022-02-23 | 09:30 – 11:30 CET | ||

| 2022-02-23 | 15:30 – 17:30 CET | ||

| Session 3 |

|

||

| 2022-03-10 | 15:30 – 17:30 CET | ||

| 2022-03-11 | 09:30 – 11:30 CET | ||

| Session 4 | |||

| 2022-03-23 | 09:30 – 11:30 CET | ||

| Session 5 |

|

||

| 2022-04-08 | 09:30 – 11:30 CEST | ||

| Session 6 |

|

||

| 2022-04-22 | 09:30 – 11:30 CEST | ||

| Session 7 |

|

||

| 2022-05-04 | 15:30 – 17:30 CEST | ||

| Session 8 |

|

||

| 2022-05-20 | 09:30 – 11:30 CEST | ||

SPIE 2022

2022-02-03

After COVID-related cancellations of previous SPIE meetings in Japan and San Diego, we are now hoping for a physical SPIE meeting in Montreal during the summer of 2022. 4MOST will of course be strongly represented, with the following abstracts having been submitted:

- 4MOST – the 4-metre multi-object spectroscopic telescope project in the assembly, integration and test phase (R. de Jong et al.)

- 4MOST – MAIT of the High-Resolution-Spectrograph (W. Seifert et al.)

- 4MOST – manufacture, assembly and test of the optical fiber system (A. Kelz et al.)

- 4MOST Calibration System: Design, Assembly and Testing (J. Pragt et al.)

- 4MOST Guiding and Wavefront Sensing cameras – Requirements and early testing (O. Bellido-Tirado et al.)

- 4MOST Low Resolution Spectrograph Alignment (F. Laurent et al.)

- 4MOST Low Resolution Spectrograph Performances (K. Disseau et al.)

- 4MOST WFC_ADC (M.Cunningham, D. Brooks, P. Doel et al.)

- The 4MOST Calibration Plan (G. Micheva et al.)

- Overall performance of AESOP, the 4MOST fibre positioner (J. Brzeski et al.)

- AESOP, the 4MOST fibre positioner – Engineering Principle (J. Brzeski et al.)

- The 4MOST facility control software on its way to a fully fledged subsystem (F. Rothmaier et al.)

LRS-A Local Acceptance Review

2021-12-20

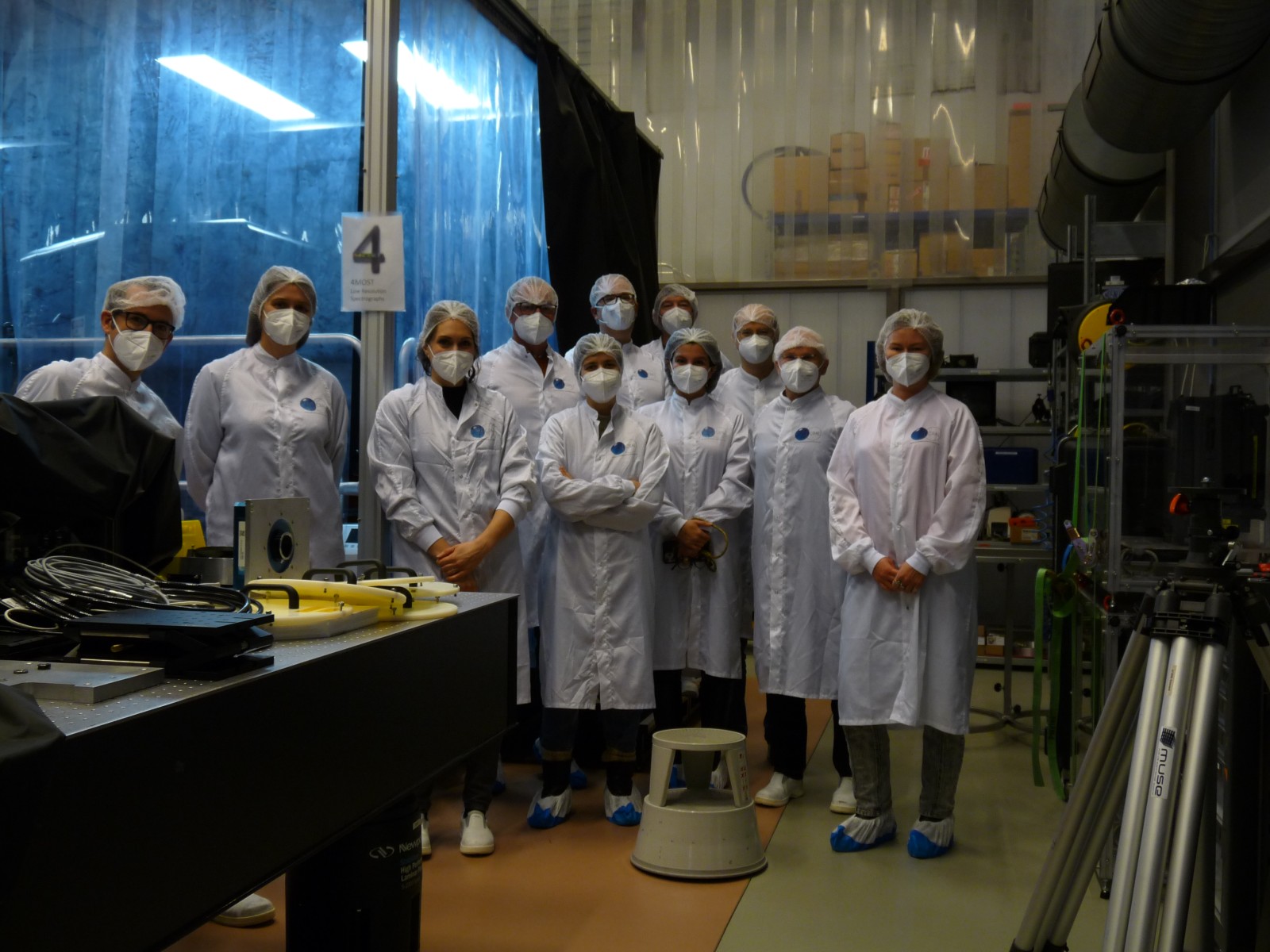

A team from the 4MOST Project Office visited CRAL on 15-16 December 2021 to conduct the Local Acceptance Review (LAR) for the first Low-Resolution Spectrograph (LRS-A). The purpose of the LAR is to assess whether a subsystem is mature and complete before shipping it to the AIP for integration. During the weeks prior to the physical meeting, the deliverable documentation was submitted and reviewed, resulting in a set of comments and questions. At the two-day LAR meeting in Lyon the technical performance and cost were reviewed, the hardware was inspected, the instrument was operated using engineering GUIs, and more. 4MOST project members from MPIA and ESO also participated remotely.

In general, the performance of LRS-A was found to be excellent and no major issues were identified. Issues related to documentation and product assurance are well advanced and on par with expectations at this stage of the project. A list of Action Items has been produced as a result of the LAR. The plan is now for LRS-A to be shipped to Potsdam sometime in Q1 of 2022, with the exact date depending on other system integration activities.

The Project Office wishes to thank the LRS team at CRAL for their dedicated and competent work and superb collaboration. We are already now looking forward to coming back to Lyon when LRS-B is finished!

4MOST Code of Conduct released

2021-11-30

The 4MOST Code of Conduct (CoC) has recently been approved by the Science Coordination Board, the Executive Board and the ESO Director for Science, and it is now applicable to the work of all 4MOST Project members, including all Consortium Survey members. The CoC establishes important principles like open, respectful communication and a shared commitment to a set of values that include ethical conduct, civility, inclusiveness, and diversity. It also describes escalation procedures in case of conflicts. All 4MOST members will be required to confirm, once a year, that they have read the CoC and that they will adhere to it. The request to confirm the CoC (as well as basic contact details) will be launched soon by the 4MOST User Management System.

The CoC foresees the installment of at least two Ombudspersons, who will provide independent, confidential and neutral advice to members of 4MOST in case of problems or conflicts within the Project. They will also provide current information about services, programs, policies, and procedures. They will try to resolve problems through mediation or by making recommendations to the 4MOST leadership. Nominations for 4MOST Ombudsperson candidates have been solicited by the 4MOST Principal Investigator, Roelof de Jong, on 17 November 2021.

Introducing the new Project Scientists

2021-11-23

An announcement from the Principal Investigator, Roelof de Jong:

It gives me enormous pleasure to let you know that the 4MOST Executive Board has with great enthusiasm approved the two new Project Scientists for the Project:

- Karin Lind (Stockholm University, Galactic PS)

- Jon Loveday (Sussex, extragalactic PS)

Karin has a long history in in the field of Galactic Archeology in general and in modelling of stars and analysing stellar spectra in particular. Since 2015 she has been one of the IWG7 leaders, making sure that the Galactic data reduction pipelines of 4MOST are well prepared. She has a keen interest in measuring the entire Milky Way system with a single yardstick, from the bulge over the full extent of the disk and beyond to the halo and its satellite galaxies, as this will be fundamental in order to understand the interrelationship and formation history of these components. Karin brings many years of experience within 4MOST and other surveys, and is well aware of the importance of creating strong networks that are necessary to make the 4MOST Science Team a tight collaboration.

Jon has been involved in spectroscopic surveys of galaxies since 1985. He has extensive experience in developing survey strategies and in galaxy spectral analysis. He has a keen interest in making sure that the extragalactic 4MOST Surveys are competitive within the broader astronomical community and sees a lot of opportunity in exploiting synergies with other new large facilities in the Southern hemisphere like Rubin Observatory, the SKA pathfinders, and the Antarctic CMB experiments. During OpR2 he was performing quality control for the CR and WAVES Surveys. He sees it as one of his main tasks to bring together the requirements of all the different Surveys in order to find the best compromise for survey strategy.

Please welcome Karin and Jon and help them wherever you can to get them up to speed with the many facets of 4MOST with which they may not be so familiar yet. I am looking forward to collaborating with them in the next few years to achieve important milestones like the onboarding of the Community Surveys, finalising the survey strategy and preparing for instrument commissioning.

Karin and Jon succeed Sofia Feltzing and Richard McMahon, respectively, who have been the 4MOST Project Scientists since 2013. Sofia and Richard have played a key role in shaping the science programme and its organisation from the early Preliminary Design Phase until now. The 4MOST leadership is very grateful for their relentless efforts and their intense dedication to making 4MOST a success.

Save the date: Science Team and All-Hands Meetings 2022

2021-11-10

Please mark your calendars:

The 4MOST Science Team Meeting 2022 will be hosted by UHH in the beautiful city of Hamburg on 23–25 May 2022. This will be the first ST meeting to include the Community Surveys.

The 4MOST All-Hands Meeting 2022 will take place at the AIP in the charming city of Potsdam on 19–23 September 2022.

Both meetings are currently planned as in-person events, but remote access will be available.

AESOP integration

2021-10-29

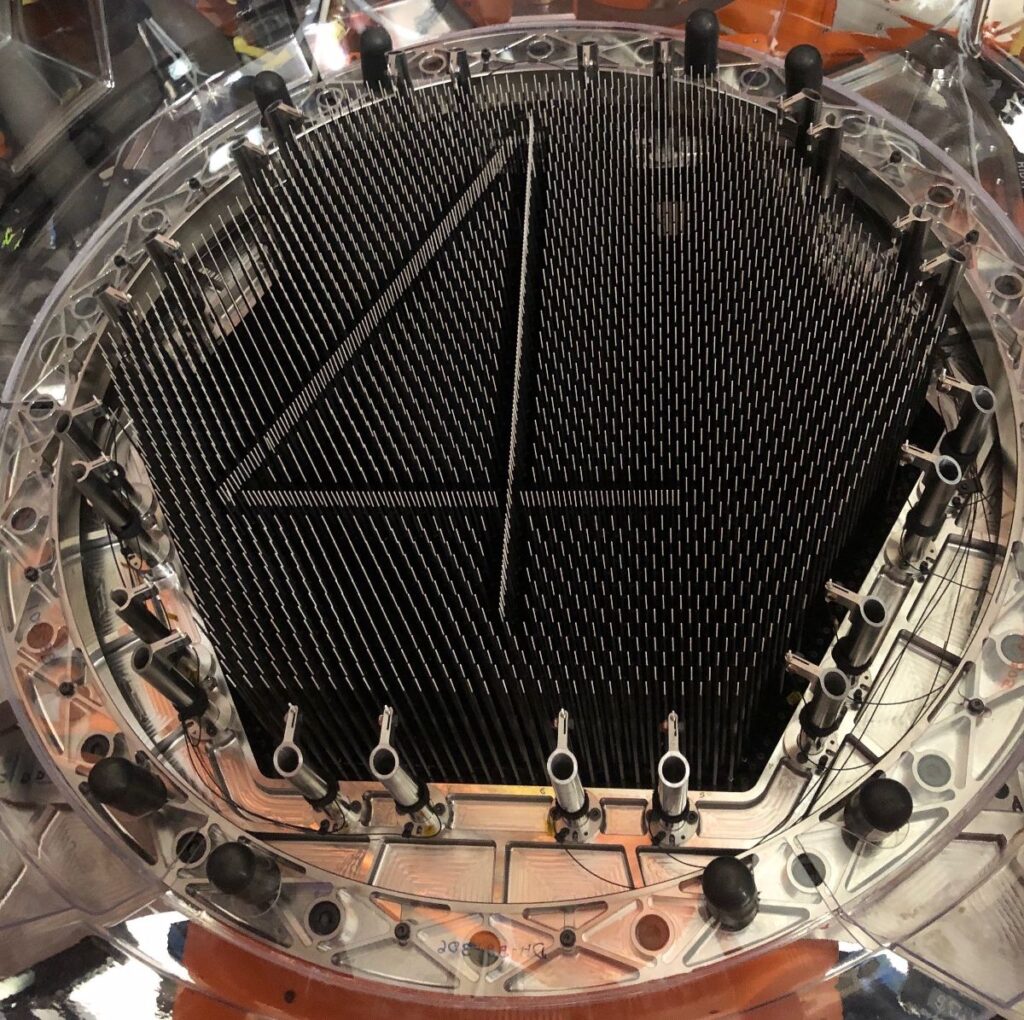

One of the core components of 4MOST is a fibre positioner, called AESOP (Australian-European Southern Observatory Positioner), which was designed and built by the Australian Astronomical Optics (AAO) Department of Macquarie University in Sydney in the framework of ESO's partnership with Australia. AESOP is the first major subsystem of 4MOST to have arrived at the Leibniz Institute for Astrophysics Potsdam (AIP) for integration.

The AESOP system, which is based on innovative AAO technology, includes the positioner with its 2436 fibres, the positioner housing, the electronics and the electronics enclosures. The fibres are arranged in a hexagonally shaped grid and can be pointed very precisely to collect the light from stars and other objects in the sky. The fibres relay the light to three optical multi-object spectrographs that will measure the spectral properties of the observed objects simultaneously, and thus give clues on the chemical structures and movement of different regions of the Milky Way, among other things. The most important requirement for AESOP is that all fibres must be repositioned within 1 minute with an accuracy of 10 micrometres – about one fifth the thickness of a hair. When the fibres reach their new positions, they are back-illuminated with red light which is recorded by high-resolution cameras to check the positions of the fibre ends before starting a sky exposure. The better the accuracy and speed, the more light from an object will be caught in as little time as possible.

In August, the completed fibre positioner was delivered from AAO in Sydney to AIP in Potsdam. This is the first delivered major component for 4MOST and, once unpacked and reintegrated, it marks the start of 4MOST system integration at AIP's integration hall. "After more than four years of design and analysis work, followed by 3 years of manufacturing and integration, it was very exciting to receive the finished AESOP for system integration," reflects Joar Brynnel, Project Manager of 4MOST at AIP. "Test results from Sydney show excellent performance and we are very happy to start testing AESOP in Potsdam and continue the great collaboration with our partners and colleagues in Australia."

Nominally, the plan was for the AAO team to travel to Potsdam and lead the re-integration and test of the AESOP fibre positioner. Due to COVID travel restrictions in and out of Australia, this was not possible. The situation posed difficult problems for the Potsdam engineering staff, who would normally rely on the collaboration with their Australian colleagues for the unpacking and delicate assembly of AESOP. The teams have now devised an alternative plan where the work will be carried out by staff from the European 4MOST partners under the remote supervision of AAO technical staff. This has started with the arrival of a support team from the Max Planck Institute for Astronomy and the Landessternwarte, both in Heidelberg, on 25 October.

Dr Roelof de Jong, Principal Investigator of 4MOST, emphasises the importance of this step: "It is amazing to reach the milestone of AESOP unpacking and assembly in Potsdam. The fibre positioner is at the heart of the facility and we can now start assembling and testing the full instrument around it before shipping everything to Chile." The completion of the instrument in Europe and delivery to Chile is currently planned for May of 2023.

"AAO-Macquarie University is proud to engage and work closely with major observatories around the world to deliver innovative new instruments based on the new and emerging technologies, like AESOP, that we are creating," said AAO-Macquarie University's AESOP Project Manager Scott Smedley.

The text above has been reproduced (with minor modifications) from this AIP press release. See also this UWA press release and this ESO twitter thread.